Cygnus 1 Ultrasonic Thickness Gauge

MULTIPLE ECHO ULTRASONIC DIGITAL THICKNESS GAUGE

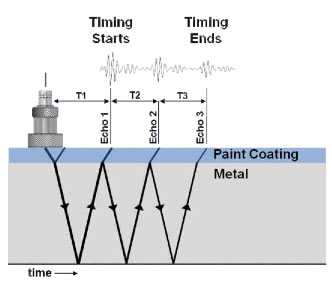

The Cygnus 1 Atex ultrasonic thickness gauge is designed for safely measuring metal thickness to determine wastage or corrosion in potentially explosive environments. By using multiple echo technology the metal thickness gauge measurements are error checked using 3 return echoes to provide repeatable, reliable results. Supplied ready to use in a protective carry case with 2 rechargeable batteries, the Cygnus 1 Intrinsically Safe can achieve up to 10 hours of continuous testing before recharge is necessary

- Certified Intrinsically Safe to: ATEX Marking Group I & Group II, CSA Class 1 Group A, B, C & D Division 1

- For use in Zone 0, Zone 1 hazardous areas

- No plant shutdown or hot work permit necessary

- Heavy duty sealed unit – IPX5 and IPX7 rated – highly water / dirt / dust resistant

- Rugged, durable, shock proof construction

- Stable calibration – linear accuracy – no zero adjustment

- Self verification of the measurements to ensure accuracy

- Various probe options

- Two rechargeable batteries with charger

- Displays sound velocity settings

- Echo strength indicator to aid measurement

- Bright LED display with polarised filter

- Probe frequency selectable

- Low battery warning

- Metric / Imperial switchable

- Also approved for use in mines

I M 1 Ex ia I Ma (Ta = 0 to 45 C)

II 1 G Ex ia IIC T6 Ga (Ta = 0 to 45 C)

Benefits of Cygnus Multiple Echo

| Cygnus 1 Specifictions | |

|---|---|

| Materials | Sound velocities between 2000 and 7000 m/s (0.059 and 0.31 in/microsec) – covers virtually all common engineering materials |

| Measurement Range in Steel | 3 – 250 mm (0.110″ – 9.995″)

with 2.25 MHz probe with 5.0 MHz probe |

| Accuracy | 0.1 mm (0.005″) when calibrated in accordance with Cygnus Instruments Calibration Procedures |

|

Resolution

|

0.1 mm or 0.05 mm (selectable) (0.005″ or 0.002″) |

| Probes | Single crystal soft-faced compression 6 mm (1/4″) – 5 MHz 13 mm (1/2″) – 2.25, 3.5 or 5 MHz 19 mm (3/4″) – 2.25 MHz (Lower frequency probes offer better penetration on heavy corrosion/coatings) |

| Power |

NiMH rechargeable battery pack

|

| Battery Life | 10 hours’ continuous operation |

| Display | Large, bright LED display |

| Size | 235 mm x 75 mm (9.252″ x 3″) |

| Weight | 1040 g (34.7 oz) with remote probe (inc. batteries) |

| Operating Temp. | -10°C to +50°C (14°F to 122°F) |

| Certification | ATEX {Ex} I M 1 Ex ia I Ma (Ta = 0 to 45 C) {Ex} II 1 G Ex ia IIC T6 Ga (Ta = 0 to 45 C) CSA Class 1 Group A, B, C & D Division 1 |

| Protection | IPX5 & IPX7 |

| Compliance | CE, British Standard BS EN 15317:2007 (Specification for the characterisation and verification of ultrasonic thickness measuring equipment) |

| Warranty | 3 years on gauge, 6 months on probe |

- Measures remaining metal thickness on corroded and coated structures

- All measurements are error checked using 3 return echoes to give repeatable, reliable results

- Accepted by all major classification societies

- Greatly reduces inspection time and costs

- Echo strength indicator to aid measurement